Deburring and chamfering system for small metal components

Deburring and chamfering system for small metal components

![[ Image ]Deburring and chamfering system for small metal components](./file/114/ws056_main.jpg)

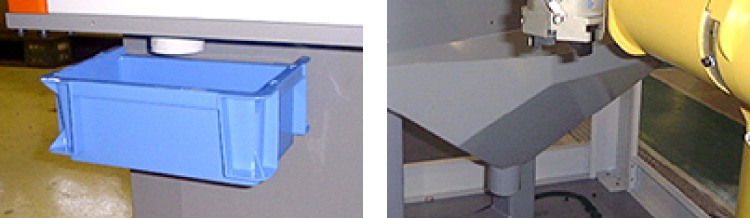

Best suited for finishing small metal components

By grasping a workpiece, machining using multiple tools is possible. Compared to a tool grasping type, machining within a narrow range of motion can be performed. Space saving is realized.- Arrangement of multiple workpieces at the main unit base side made possible in advance. The burden of loading/unloading workpieces is lightened.

- Safety guards considering dust processing are adopted. As an option, a dust collector can be installed separately. The system can be customized to suit the customer's environment.

- The layout is designed so that all operations can be performed at the front of the machine, such as checking the operation panel and the operation of the air equipment, and performing teaching and tool replacement. Usability and maintainability will be increased.

Applications

| Application examples Automobile parts Computer parts |

|

|---|

| Footprint | W1400mm x D1000mm+α x H1900mm |

|---|---|

| Handling method | Workpiece grasping type |

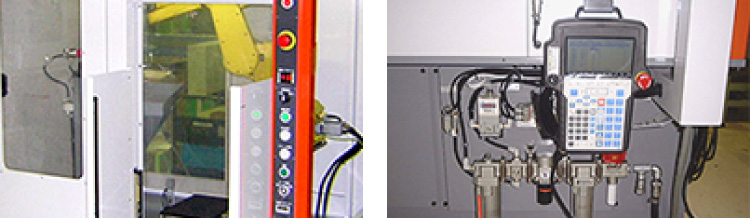

Dimensions

![[ Image ] Dimensions](./file/116/ws056_size_img01.gif)

Specifications

| Type | WS056 (part handling deburring and chamfering machine) |

|---|---|

| Footprint | W1400mm×D1000mm+α×H1900mm |

| Wight | 800kg |

| Application examples |

Deburring and chamfering of small metal parts. Parts must have areas within 200 mm × 200 mm and weights at or below 1 kg. |

| Workpiece supply and removal | Manual supply/removal by the operator to/from a fixture/pallet on the single row air shuttle (standard) |

| Machine type selection | 1–99 numerical selection system |

| Robot | FANUC Robot LR Mate 200iD/7 customized by Yamaha |

| Power supply | 3-phase, 100 to 220V+10%/-15% AC, 50/60Hz |

| Power supply capacity | 5kVA |

| Air supply | Air pressure: 0.4 MPa Consumption: 100 NL/min |

| Others | Custom designs are available. |

Contact point

Inquiry by email

Inquiry by phone

+81-53-467-3601

![[ Image ] Binocular frames](./file/123/robots_work_img01.jpg)

![[ Image ] Computer parts](./file/122/robots_work_img02.jpg)

![[ Image ] Camshafts](./file/124/robots_work_img03.jpg)