Peripherals supporting finishing

Peripherals supporting finishing

![[ Image ] Peripherals supporting finishing](./file/403/peripheral_tools_main.jpg)

A wide range of peripheral tools, such as a tool holder provided with finishing adaptation control and tool change equipment, help realize manpower saving and increase productivity.

Two handling methods

![[ Image ] Workpiece grasping: The robot holds a workpiece.](./file/515/peripheral_tools_hd_img01.jpg)

Workpiece grasping: The robot holds a workpiece.

![[ Image ] Tool grasping: The robot holds a tool.](./file/516/peripheral_tools_hd_img02.jpg)

Tool grasping: The robot holds a tool.

Tool handling specifications

Thrust floating

The use of a linked structure for linear sliding both improves rigidity and enables smooth floating. By profiling the irregularities in the workpiece surface and applying tools at a given level of force, it is possible to machine in a variety of directions from flat surfaces to curved surfaces, while absorbing variances in workpiece dimensions and clamps. The robot applies thrust control that presses a tool at a given level of force without being affected by the tool angle.Wheel tool holder

![[ Image ] Wheel tool holder](./file/169/peripheral_tools_th_img01.jpg)

Head image

| Machining [Application] |

|

|---|---|

| Details |

|

Disk tool holder

![[ Image ] Disk tool holder](./file/170/peripheral_tools_th_img02.jpg)

Head image

| Machining | Polishing |

|---|---|

| Details |

|

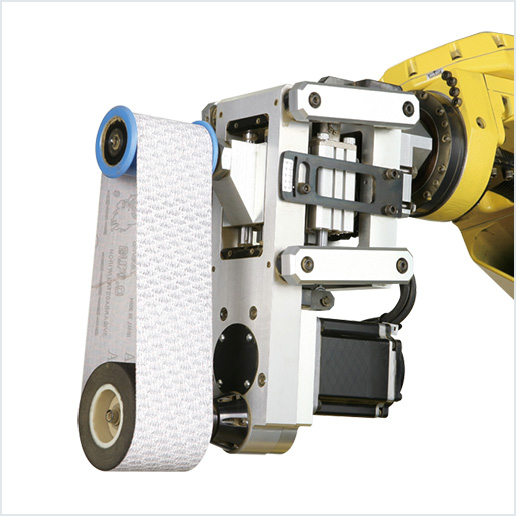

Belt sander tool holder

![[ Image ] Belt sander tool holder](./file/171/peripheral_tools_th_img03.jpg)

Head image

| Machining [Application] |

|

|---|---|

| Details |

|

Radial tool holder

An escape mechanism in the radial direction (360°) is provided to make it easy to deal with burr irregularities. The floating power (centripetal force) can be configured as desired in the program. This holder is suitable for removing tiny burrs using a rotary bar.Radial tool holder

![[ Image ] Radial tool holder](./file/172/peripheral_tools_th_img04.jpg)

Head image

| Machining [Application] |

|

|---|---|

| Details |

|

Buffing tool holder

This holder is suitable for polishing the surface of large workpiece.Buffing tool holder

![[ Image ] Buffing tool holder](./file/182/peripheral_tools_th_img05.jpg)

Head image

| Machining [Application] |

|

|---|---|

| Details |

|

Tool grasping: Tool holder based tool changer

For each tool holder, a tool changer for automatically changing tools is available. This increases work efficiency and contributes to manpower saving.Tool changer

![[ Image ] Tool changer](./file/175/peripheral_tools_th_img06.jpg)

| Wheel tool holder |

|---|

![[ Image ] Wheel tool holder](./file/169-1/peripheral_tools_th_img01.jpg) ![[ Image ]](./file/208/peripheral_tools_th_img07.jpg)

|

Sandpaper disks changer

![[ Image ] Sandpaper disks changer](./file/176/peripheral_tools_th_img08.jpg)

| Disk tool holder |

|---|

|

Belt sander changer

![[ Image ] Belt sander changer](./file/177/peripheral_tools_th_img09.jpg)

| Belt sander tool holder |

|---|

|

Tool grasping: Wax supplier

A wax supplier applied to buffing tool holders. Automatic wax supply increases work efficiency and contributes to manpower saving.Solid wax supplier

![[ Image ] Solid wax supplier](./file/178/peripheral_tools_th_img10.jpg)

| Buffing tool holder |

|---|

|

Liquid wax supplier

![[ Image ] Liquid wax supplier](./file/179/peripheral_tools_th_img11.jpg)

| Buffing tool holder |

|---|

|

Tool grasping: Added NC axis

A standard turntable using a robot's optional axis. This table rotates in synchronization with the robot and is effective at machining a cylinder type workpiece as a workpiece rotation positioning unit.Added NC axis

![[ Image ] Added NC axis](./file/181/peripheral_tools_th_img12.jpg)

| Application | Cylindrical |

|---|

Workpiece handling specifications

Sander heads

This head rotates a sanding belt and performs grinding. As a standard feature, it is provided with a mechanism that swings a contact wheel to absorb workpiece variations.Vertical sander head

![[ Image ] Vertical sander head](./file/180/peripheral_tools_wh_img01.jpg)

Head image

| Machining | Deburring |

|---|---|

| Details |

|

Horizontal sander head

![[ Image ] Horizontal sander head](./file/183/peripheral_tools_wh_img02.jpg)

Head image

| Machining | Polishing |

|---|---|

| Details |

|

Buffing head

A tool for performing polishing by rotating a wheel tool such as buff and a brush.Vertical swing buffing head

![[ Image ] Vertical swing buffing head](./file/185/peripheral_tools_wh_img04.jpg)

Head image

| Details |

|

|---|

Horizontal buffing head

![[ Image ] Horizontal buffing head](./file/184/peripheral_tools_wh_img03.jpg)

Head image

| Details |

|

|---|

Tool heads

Tool heads are arranged around the robot to suit the machining usage.Thrust tool head (1)

![[ Image ] Thrust tool head](./file/187/peripheral_tools_wh_img05.jpg)

Head image

| Machining | Inner surface polishing |

|---|

Thrust tool head (2)

![[ Image ] Thrust tool head](./file/189/peripheral_tools_wh_img06.jpg)

Head image

Radial tool head

![[ Image ] Radial tool head](./file/190/peripheral_tools_wh_img07.jpg)

Head image

| Machining | Outer surface machining |

|---|

Oscillating rasp head

![[ Image ] Oscillating rasp head](./file/191/peripheral_tools_wh_img08.jpg)

Head image

Contact point

Inquiry by email

Inquiry by phone

+81-53-467-3601

![[ Image ] Polishing [Aluminum product]](./file/188/peripheral_tools_work_img02.jpg)