Chamfering system for aluminum wheels

Chamfering system for aluminum wheels

![[ Image ] Chamfering system for aluminum wheels](./file/136/tr057ac_main.jpg)

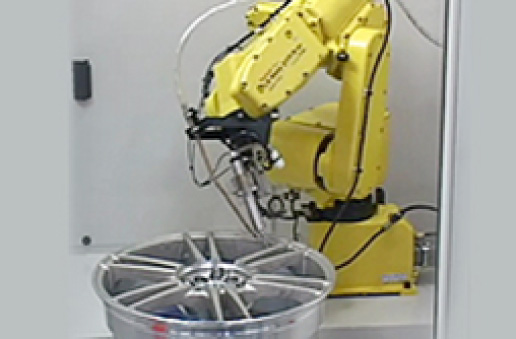

Machining burrs formed at decorative wheel rims removed

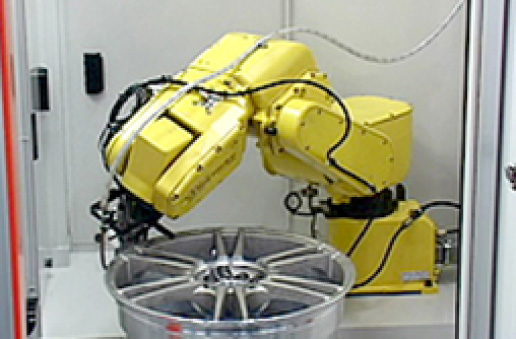

A head specially designed for aluminum wheels removes burrs formed on the decorative wheel rims. With a dedicated tool holder, high-quality chamfering is realized.- A tool holder specially developed for chamfering decorative aluminum wheel rims is installed on a small robot.

- Space saving realized by an NC index rotating the workpiece to supplement the robot's range of motion.

- Automatic origin indexing is performed by a dedicated sensor. This made positioning work during setup easy.

Applications

| Application examples |

|

|---|

| Footprint | W1250mm x D1250mm+α x H2000mm |

|---|---|

| Handling method | Tool grasping type |

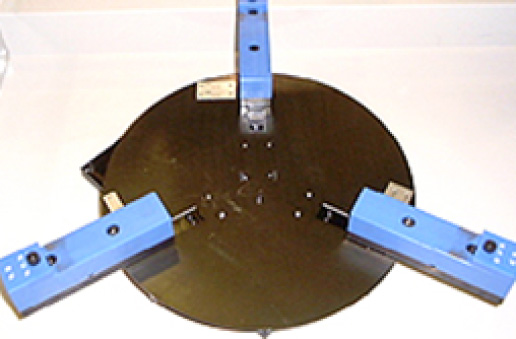

Dimensions

![[ Image ] Dimensions](./file/141/tr057ac_size_img01.gif)

Specification

| Type | TR057AC (Decorative aluminum wheel rim chamfer machine) |

|---|---|

| Footprint | W1250mm x D1250mm+α x H2000mm |

| Weight | 800kg |

| Application examples | 14–20-in Workpiece clamp jig (change attachments every 3in or 5in) |

| Workpiece supply and removal | Manual supply and removal by operator |

| Equipment specifications | Workpiece NC index (using robot added axis NC motor) Workpiece auto-centering clamp Workpiece automatic origin detection system |

| Tool holder | Air-driven motor, floating mechanism for deburring |

| Machine type selection | 1–99 numerical selection system |

| Robot | FANUC Robot LR Mate 200iD/7 customized by Yamaha |

| Power supply | 3-phase, 200 to 220V+10%/-15% AC, 50/60Hz |

| Power supply capacity | 1.2kVA |

| Air supply | Air pressure: 0.5 MPa Consumption: 300 NL/min |

| Others | Automated door with an area sensor (can be connected to a synchronizer) |

Contact point

Inquiry by email

Inquiry by phone

+81-53-467-3601

![[ Image ] Aluminum wheels for automobile](./file/137/robots_work_img07.jpg)