Aluminum wheel leak testing

Achieving high-precision 100% inspection, which is difficult with immersion-type systems

Overview

Target

Automobile parts manufacturersBackground

Thorough quality management is required at aluminum wheel manufacturing sites, due to increased awareness of reliability and safety in recent years. However, low repeating accuracy and reproducibility are issues with conventional immersion-type inspection.Application examples

Aluminum wheels![[Image] Aluminum wheels](./file/927/lt2_img01.jpg)

The issue is human error in inspection results

Aluminum wheels cast by the die casting method fill dies with molten metal by injection at a high speed, and cool down and solidify in a short time.

Inspection is required because at that time, casting defects that cause air leakage in tires such as pinholes may occur.

However, with conventional immersion-type inspection, the accuracy of inspections performed in a short time period is low, and there is a risk of complaints due to variations caused by human errors.

Inspection is required because at that time, casting defects that cause air leakage in tires such as pinholes may occur.

However, with conventional immersion-type inspection, the accuracy of inspections performed in a short time period is low, and there is a risk of complaints due to variations caused by human errors.

Challenge

There are many human errors in the conventional immersion-type leak inspection and there is a risk of complaints.Points

- Defects may be overlooked

- Quantitative management is not possible

- Post-processing is required after immersion

Conventional method

Immersion-type leak tester![[Image] Immersion-type leak tester](./file/926/lt2_img02.png)

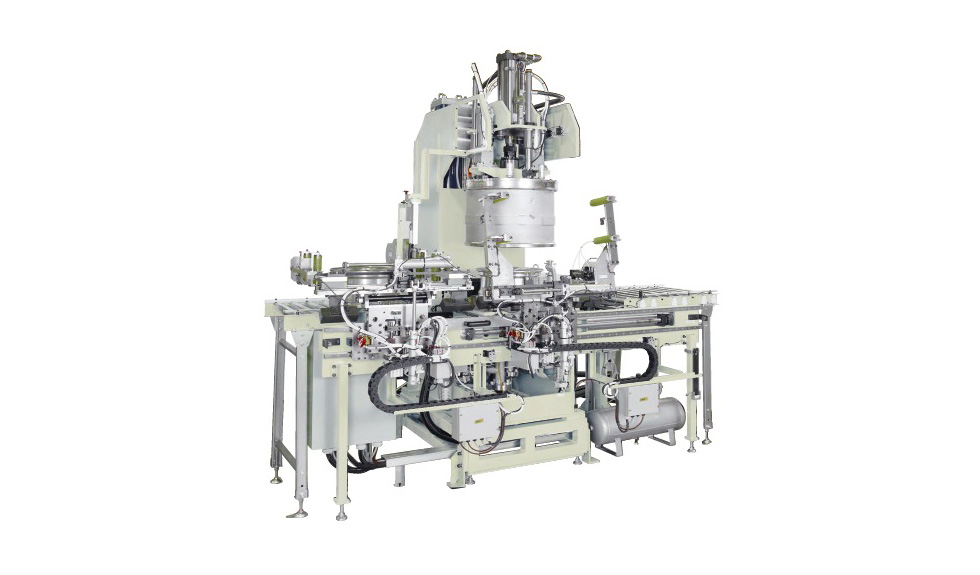

Resolved with helium leak testers

Enables stable and high-precision inspection, with was difficult with the immersion-type inspection, with the high inspection accuracy characteristic of the helium gas inspection method.

Gas sensors directly detect gas that leaks from a pinhole, so this method is not affected by human errors.

Easy to operate and does not require operator skill.

Compared to the immersion type, which is difficult to automate, inspection can be fully automated and accelerated.

Gas sensors directly detect gas that leaks from a pinhole, so this method is not affected by human errors.

Easy to operate and does not require operator skill.

Compared to the immersion type, which is difficult to automate, inspection can be fully automated and accelerated.

Solution

Introducing a helium-type leak testing system enables anyone to carry out 100% inspection with a high level of precision.Points

- High reliability, with no human error

- High sensitivity gas direct detection method

- Immediate response supports mass production

Solution

Helium-type leak tester![[Image] Helium-type leak tester](./file/925/lt2_img03.png)